Early February the US announced it would issue tariffs on its top three trading partners – Mexico, Canada, and China which account for more than 40% of US imports. The tariffs were set at a rate of 25% imported materials from Canada and Mexico. Reportedly, energy imports from Canda, such as crude oil, were to be subject to a lower tariff rate of 10%. On Feb 3rd, tariffs on Mexico and Canada were paused for a month while the 10% import duty on Chinese imports went into effect on Feb 4th.

Today’s globally connected economy means the impact of these tariffs extends well beyond North America. The changing tariff announcements, policies, and trade conflicts are shifting companies’ perspectives of the global trade landscape, forcing them to rapidly assess and understand implications to customer demand, the supply network, fulfillment, and supply chain added cost dimensions.

There is a staggering amount of money at stake. Trade in goods and services between Canada and the US was about $920 billion in 2023, while trade between Mexico and the US was nearly $900 billion, according to data from the US Department of Commerce.

As initial rounds of tariffs are announced, (then postponed), and implemented, supply chain leaders need to quickly find the right degree of flexibility and agility in a meaningful way to strengthen their response and, where possible, build competitive advantage. The back-and-forth, go/no go narrative leaves many unsure of what to do next, causing some to freeze and do nothing. In fact, there are actions, even in an uncertain environment, every company can (and should) do.

The immediate short-term action of many organizations has been:

- Pass on costs to customers

- Absorb costs and accept the associated financial impacts.

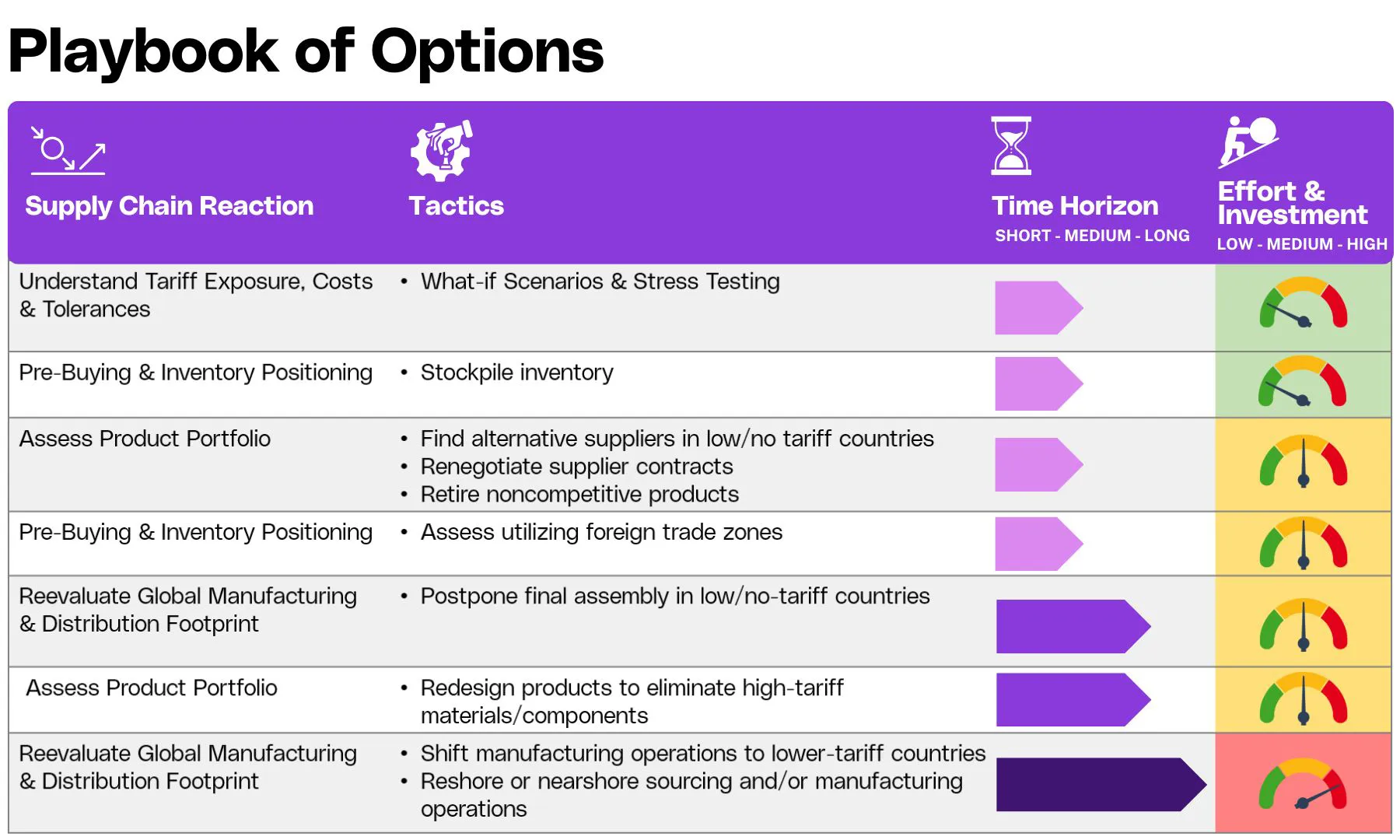

These only begin to scratch the surface of what can be done. Leading organizations are looking at a range of strategies and assessing further actions that can help maximize their competitive positioning for success. One of the short-term options that requires relatively low effort and investment is to develop a playbook outlining various scenario options. Here is a short list of a few options.

This gives companies the ability to look at different options and scenarios while evaluating a range of real-world variables, enabling supply chains to dynamically evaluate trade-offs and risk.

7 Steps to Consider

1. Understanding Tariff Exposure, Costs and Tolerances

The first step is to account for which regions, products, and services are impacted (or could be impacted) by the tariff changes. Next, identify how much tariff-induced cost increases can be absorbed. For instance, if tariffs raise costs for certain components in your bill of materials by 10%, does your business remain profitable? What about at 25%? Running sensitivity analyses on metrics like cost of goods sold and profitability helps businesses understand where their thresholds lie. Ask yourself:

- If we pass on tariff costs to customers or consumers, what impacts will this have on demand?

- If we absorb tariff costs, what impacts will this have on our margins and profitability?

2. Assess your Product Portfolio

Tariff volatility can push certain products or operations to their limits, forcing organizations to evaluate their viability and adjust to new market realities. Decisions must be made to either retire non-competitive products, or adapt through actions such as cost-cutting measures, product redesigns, renegotiate supplier contracts, and more. Tariff volatility also presents an opportunity to capitalize on competitor weaknesses and capture market share and drive growth.

3. Pre-Buying and Inventory Positioning

Companies can mitigate immediate impacts by purchasing additional inventory before tariffs take effect. Companies utilizing foreign trade zones (FTZs) to store goods without incurring immediate tariffs, need to strategically plan to pay duties before new tariffs take effect to optimize cost-savings of the FTZ. However, it is important to note that this strategy may have limited shelf life as trade policies continue to rapidly evolve.

4. Supplier and Broader Ecosystem Impact

As organizations navigate tariff changes, they must consider the potential supply risks to critical suppliers, the ripple effects on ecosystem partners such as customers and transportation providers, and explore alternative mitigation strategies, including diversifying manufacturing and shipping locations, to minimize disruption and ensure business continuity.

- Do we face potential supply risks if critical suppliers face an increase or decrease in demand?

- How will other ecosystem partners — including customers, transportation and partners — be impacted by the tariff changes?

- What alternative mitigation actions can we take? For example, can we change where product destined for the U.S. is manufactured and shipped from?

5. Reevaluating Global Manufacturing Footprints

Tariffs targeting specific countries or industries may prompt a shift in manufacturing locations. For example, if some goods from China are heavily taxed, could operations shift to Mexico, Vietnam, or even the United States? Scenario planning helps companies evaluate the financial and logistical implications of these moves.

6. Competitor Analysis

Not all industries and companies will face tariffs equally. Understanding how competitors are impacted—whether they manufacture locally or abroad—can highlight vulnerabilities or opportunities to gain market share.

- How will tariffs impact our enterprise’s competitive positioning within the market?

- Will our competitors be more or less disadvantaged than us?

7. Modeling Long-Term Impacts

Plans must also account for scenarios where tariffs are delayed, reduced, or withdrawn entirely. For instance, if a company invests in reshoring production but the new tariffs don’t materialize, can the higher production costs be offset through a “Made in America” marketing strategy, or shorter lead times?

The Bottom Line

The one certainty in today’s global landscape is uncertainty. Today’s fast pace of change and complexity exceeds human capacity. Supply chain leaders need the ability to quickly make the most optimal and probable decisions, while considering thousands of variables.

It’s critical to ensure you’re acting on the most relevant information to your business at the right time, while accounting for changes in the supply chain network to help you maximize an opportunity and mitigate risks.

Let us show you how the Atlas Planning Platform can help you leverage AI-powered probabilistic what-if scenarios to take proactive action and stay ahead of the evolving landscape.

Watch our webinar Rise Above Tariffs - How to Turn Volatility into Supply Chain Opportunity, and stay tuned with our upcoming blogs providing insights and actionable advice to help you identify next steps in your supply chain strategy.