Volatile New Normal

On February 19, 2020, the International Monetary Fund's managing director, Kristalina Georgieva predicted that uncertainty and volatile market conditions would become the norm, saying that "uncertainty is becoming the new normal" in a virtual meeting of G20 leaders, warning them about the financial effects of the impending global health crises. Nearly ten months later, her prediction has been correct on all counts. Financial markets have become unstable and so have the producers and consumers that support said markets.

Demand forecasting has become increasingly challenging due to:

- Regular disruptions (like lockdowns, trade restrictions, and shelf-life limitations)

- Changing consumer habits (unemployment, stimulus checks, and overall reduced consumption)

- Lack of clarity on consumer demand exacerbated by the slow responses from unprepared businesses

However, accurately forecasting demand and planning for shocks is far from impossible. Over the past months, supply chain experts at John Galt Solutions have been developing methods and solutions that companies can integrate into their planning processes to become more resilient and cope up with the volatile new normal. In a recent interactive workshop, "The Volatile New Normal - Improving Demand Forecast", Matt Hoffman, John Galt's VP of Customer Success discussed the demand shocks, changes in consumer habits, and volatile disruptions that are challenging companies in 2020 and how they can overcome them going forward.

Defining The "New Normal"

IMF chief Georgieva isn't alone in her assessment of an uncertain future. Other IMF chiefs in more recent statements have expressed their concern about the economic recovery from COVID-19. IMF's chief economist, Gita Gopinath sees "profound uncertainty" about the global recovery. Many companies are under the impression that the world will go back to how it was in 2019 soon after a vaccine is globally available. However, other sources will tell you that global markets are expected to recover slowly in a post-pandemic world full of disruptions. How do you plan your supply plan when dealing with these unknows?

The ideal course of action for companies now is to adopt new practices and introduce policy changes to make their supply chains resilient to disruptions and their demand forecasting more accurate despite frequent market swings. In order to do this, we must first identify the challenges that will shape and define the "new normal":

Holiday season: Holiday seasons have historically been an important period for companies and while a short-term increase in sales is still expected this year, it will most likely not reach 2019 levels, nor will it be uniform across states and countries.

Holiday season: Holiday seasons have historically been an important period for companies and while a short-term increase in sales is still expected this year, it will most likely not reach 2019 levels, nor will it be uniform across states and countries. Election results: The new normal will also be driven by policy changes by the new administration that will likely affect not only domestic supply chains and sales but also global trade.

Election results: The new normal will also be driven by policy changes by the new administration that will likely affect not only domestic supply chains and sales but also global trade. Vaccine and recovery: With multiple vaccines currently undergoing human tests, we can expect a COVID-19 vaccine to be available in Q1 of 2021. However, there are two important factors. First, vaccine production capabilities will still be limited, and vaccination will not be uniform across different geographical areas and demographics. As a result, recovery will be a slow process, potentially going into 2022.

Vaccine and recovery: With multiple vaccines currently undergoing human tests, we can expect a COVID-19 vaccine to be available in Q1 of 2021. However, there are two important factors. First, vaccine production capabilities will still be limited, and vaccination will not be uniform across different geographical areas and demographics. As a result, recovery will be a slow process, potentially going into 2022. Market noise: Noise is perhaps the most important factor in demand forecasting and will be even more important in 2021 as there is a lot of misinformation still. To make demand forecasts as accurate as possible, companies need to identify demand signals after harmonizing data from multiple sources, effectively cleansing the data in the process.

Market noise: Noise is perhaps the most important factor in demand forecasting and will be even more important in 2021 as there is a lot of misinformation still. To make demand forecasts as accurate as possible, companies need to identify demand signals after harmonizing data from multiple sources, effectively cleansing the data in the process.

Combating Volatility and Uncertainty with Resilient Technologies

Resilience, agility, and scalability have been the core tenets of modern software for a while now and these characteristics are reflected in modern demand forecasting platforms. The technologies by these platforms are architected to combat volatility and uncertainty with advanced capabilities that boost resilience.

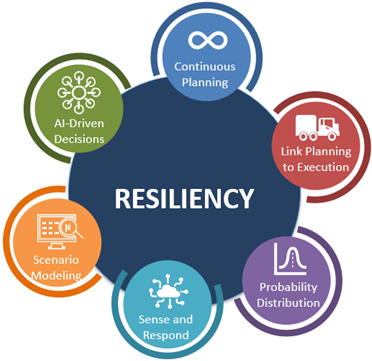

After introducing supply chain resiliency in hundreds of companies, John Galt Solutions has identified 6 key capabilities that are critical to enabling resiliency:

-

Continuous Planning

Companies need now more than ever a digital supply chain planning platform that delivers a continuous planning environment. This continuous planning environment automatically integrates internal and external data sources into the planning environment and seamlessly synchronizes multiple planning horizons (hourly, daily, weekly, monthly, quarterly, annual, etc) in real-time. A unified data model provides the underlying architecture and strong foundation to support a continuous planning environment. John Galt's Atlas Planning Platform is precisely designed to enable a continuous planning environment.

-

Link Planning to Execution

To manage risk and gain visibility into the supply chain, companies will need to incorporate short term planning signals (those traditionally found in the execution layer such as transportation, IoT, external data sources, etc.) to refine longer range plans. While traditionally companies separated planning and execution functions, these areas are very slowly starting to converge. A digital supply chain planning platform helps companies break down traditional siloes by connecting to the real-world bidirectionally across diverse applications such as transportation systems and be able to continuously model changes to the plan taking into account changes in lead time, port disruptions, and beyond. Linking these short-term planning signals further drives end-to-end supply chain visibility.

-

Probability Distribution

The real world that companies operate is volatile and uncertain - be it supply chain shocks, demand variation, supplier performance, etc. Companies need to shift from asking "How accurate are our plans?" and instead take into account variability and uncertainty into the plan. Doing so will require companies to leverage supply chain planning technology that helps create a range of plans that improve the relevant probability function and determine which plans are most resilient to variability.

-

Sense and Respond

To cope with variability, companies need to tap into external data signals such as POS (point of sale), IoT, weather, distributor data, etc. to be able to detect demand and supply changes. Incorporating these data signals improves demand sensing, demand shaping and forecasting in the short-term horizon to help prioritize product deployment and react faster to specific market conditions.

-

Scenario Modelling

Having the ability to model and simulate the impact of a change in the supply chain is critical. Companies can run hundreds of scenarios and simulate virtually anything ‐ supply changes, demand changes, capacity changes, and more. Being able to test and evaluate a range of possibilities gives confidence to executives and their supply chain teams knowing that that each scenario created represents the optimal plan for a specific combination of trigger events. "What-if" scenarios give companies the ability to view, compare, collaborate, and assess the assumptions, risks, and outcomes across the supply chain.

-

AI-driven Decisions

Artificial intelligence and machine learning will play an even important role in demand forecasting than it usually does due to the growing amount of analysis that needs to be done. AI and ML technologies allow companies to automate data collection, enable stream analysis, and identify trends and patterns with greater accuracy after each new analysis.

Data Strategies and Modelling Approaches for The "New Normal"

Companies can cleanse data and remove noise associated with market disruptions to get the true demand using a combination of data strategies and modelling approaches that are critical for the volatile new normal.

Modernizing data strategies will help cater to the changing data requirements. To make demand forecasting in the uncertain markets of 2021 accurate and resilient, companies must adapt or migrate to the following data strategies:

Think Locally

Isolation was a key policy in combating the global health crisis and companies need to adapt to more isolated markets. Blanket plans covering large geographical areas and time horizons are no longer feasible. To be accurate, demand forecasting must be local, taking into consideration factors such as local COVID-19 cases (both new and existing) and movement restrictions (lockdowns and stay-at-home orders) along with explanatory data such as economic indicators, weather data, and other local demand signals such as PoS (point of sale), telemetry, and IoT data. Another great source of external data and indicators of trends and preferences is social media and search engine data.

Optimize Features

In 2021, companies are expected to collect more data in many new categories but this needs to be done without overwhelming the planning infrastructure, particularly the team. One way of processing more data without losing productivity is to standardize and optimize features. Having unnecessary features can increase the number of errors as well as processing time. One way of optimizing features is to adopt a planning platform like John Galt's Atlas Planning Platform provides that is both agile and highly customizable enabling companies to quickly introduce changes and shift focuses to analyze different types of data with high automation levels.

Consider Time Horizons

COVID-19 disruptions have a significantly smaller impact on long-term forecasts (multiple years) and the impact increases as time horizons shrink and forecasts become short-term. Companies will have to make conscious decisions in how they use time horizons in their forecasts and to not rely on long-term forecasts as they may have in the past. Ideally, companies should be using multiple models to make both long-term and short-term forecasts.

Cleanse Data

The importance of data cleansing is paramount today because of the increasing number of outliers and events that are not truly representative of real-world demand and supply. By identifying and removing such variables, the resulting forecasts become significantly more accurate.

Transform Data

Finally, data needs to be transformed before it can be used in different data modeling approaches such as regression. Data transformation involves identifying curvilinearity (square, cube, roots, and logs). Interactions, making classifications and introducing dummy variables.

Data collection and preparation is the first step, followed by in-depth analysis, modeling, and simulations. And like data strategies, the modeling approaches need to be modified for the post-pandemic world. Following are the ideal modeling approaches that companies should opt for going into 2021:

Regression

Companies that had traditionally been using time series models must switch to regression models and predictive analysis for their data analytics as the former uses historical data to make predictions and in such a volatile world, historical data won't always be representative of the future. Statistical analysis techniques such as multiple regression are forward-looking methods that establish causal relationships between factors without relying on past data which was a major limitation of time series models

Ensemble Modelling

Ensemble modelling is a method of predictive analytics by leveraging multiple modelling algorithms or different training data sets to reduce reliance on a single point of data and create forecasts that are more accurate. Combining forecasts yields substantial benefits such as significantly lower error rates and far more robust forecasts.

John Galt's Atlas Planning Platform creates and optimizes ensembles automatically for you, although simple ensembles can be built using basic tools as well. However, in order to make the most of out of your data, companies should use ensembling approaches such as bagging, boosting, and stacking.

Clustering & Segment

Clustering and segmentation are also popular methods of predictive analysis that rely on grouping similar data streams together. Companies can leverage clustering and segmentation together with machine learning algorithms to establish relationships and find contextual information that can be used to create strategies confidently.

Implementing Machine Learning to Improve Both Data and Models

Both data strategies and modelling approaches can be done manually and with relatively basic tools. However, this will be a slow process and in the Volatile New Normal, time is of the essence. To introduce the change of this scope to your planning processes quickly and reliably, infrastructure changes may be required, especially for technologies such as machine learning.

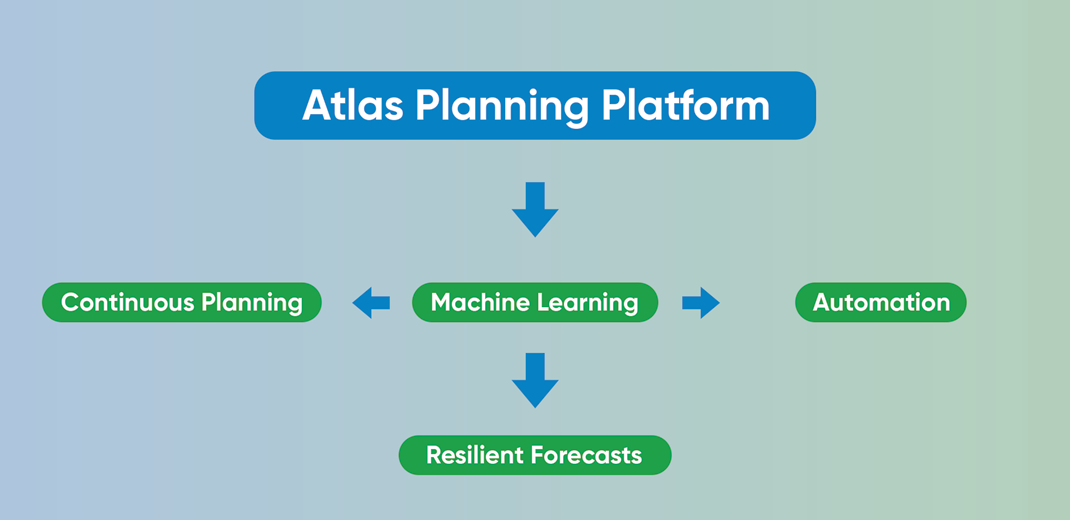

Machine learning demand forecasting has proven benefits in demand forecasting like greater accuracy and speed, rapid adaptation and agility, greater processing power, and more. The real challenge is to implement it. Machine learning is highly dependent on technology, the right IT infrastructure, and data engineers/data science team. This is why John Galt's Atlas Planning Platform has machine learning capabilities built-in. Atlas removes technological and personnel barriers by enabling companies to start ML models along with a wide range of improved business planning practices (scenario planning, event modeling, automation, etc.) on a single unified platform. Unlike traditional options, Atlas has zero coding requirements and planners can get started using out-of-the-box templates and optimized ensembles that Atlas creates for you.

Next Steps

To learn how Atlas Planning can help your company navigate the volatile new normal, please visit JohnGalt.com or email sales@johngalt.com to set up a time to talk to one of our experts.