How are you adapting your supply chain to today’s unpredictable economic landscape? From cost fluctuations and trade disruptions to evolving customer demands, the pressure is mounting to rethink traditional strategies. Now, more than ever, you need a powerful lever to improve competitiveness and ensure long-term sustainability.

In recent conversations with our teams in Asia, we explored how Malaysia’s furniture industry offers valuable insights into these challenges – and the opportunities that come with them. As one of the country’s key export sectors, the industry has been hit hard by global uncertainty, but it also highlights how technology changes the game by restoring competitiveness and building resilience.

Malaysia’s furniture industry is a significant economic pillar, contributing RM19 billion (~USD4.4 Billion) in revenue and supporting more than 320,000 jobs. Yet recent performance reveals growing pressure from multiple fronts: weakening global demand, rising operational costs, and mounting uncertainty in international trade. While many have pointed to ongoing tariff negotiations as a primary challenge, a deeper analysis shows the issues run much deeper.

Despite global turbulence, US furniture firms are showing resilience, with several reporting moderate growth. Meanwhile, competitors in Vietnam and India continue to gain market share, supported by scalable production capacity, mature supply chain systems, and robust domestic markets.

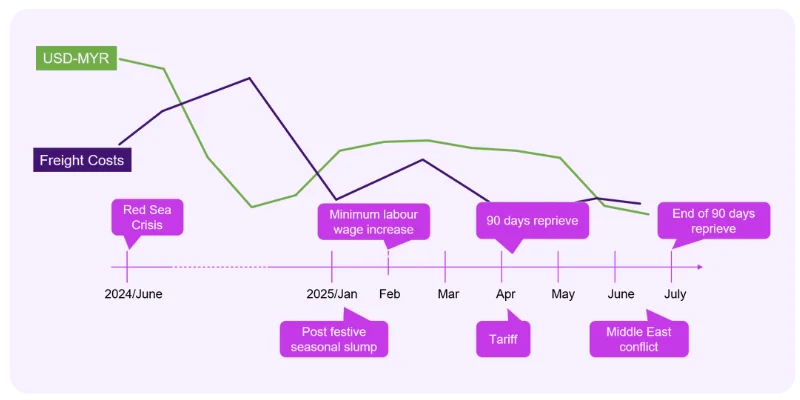

For Malaysia, the headwinds are both external and internal. Freight costs, still elevated and volatile since the Red Sea crisis in mid-2024, are eating into margins. The Malaysian Ringgit’s weakening against the US dollar has further eroded export value. Domestically, a minimum wage hike in early 2025 and stricter export documentation—particularly concerning timber origin—add more complexity and cost pressure.

Beyond Tariffs: Why a Strategic Pivot is Needed

Traditionally, Malaysian manufacturers have relied on participation in international exhibitions and trade shows to attract global buyers. These channels remain important but are no longer sufficient in a rapidly evolving global market. Policy advocacy is necessary, but on its own, it cannot guarantee operational resilience or margin protection.

The current landscape demands innovation. Increasingly, leading global manufacturers are turning to advanced technologies to improve strategic performance; from improving production efficiency and launching new product designs, to maintaining healthy cash flow and building stronger customer relationships – and it is imperative for local players to catch up.

How Supply Chain Planning Solutions Create Competitive Advantage

To truly gain a competitive edge, companies need to embed technology at the core of their operations, particularly in supply chain planning.

Investing in supply chain planning technology offers several advantages, including lower upfront costs compared to major strategic shifts (like reshoring), faster implementation timelines, and the potential for rapid ROI (Return On Investment).

Crucially, advanced supply chain planning provides the end-to-end visibility needed to navigate uncertainty, capabilities for data-driven forecasting, and real-time insights for improved decision-making – all key elements for navigating dynamic market disruptions and building supply chain resilience.

The best part? This type of technology adoption doesn’t require a massive capital investment. In fact, supply chain planning solutions offer an affordable, high-return investment path.

Here’s how supply chain planning technology helps you amplify existing strategic efforts:

1. Understand Market Trends with Greater Confidence

Challenge: Many manufacturers rely heavily on forecasts provided by key customers. This approach limits agility, especially as companies diversify their customer base.

Solution: Demand sensing powered by external data – for example, housing development trends, office occupancy rates, and consumer indexes – can help predict demand shifts before they fully materialize.

Benefit: Better alignment of production and inventory with true market needs.

2. Prepare for External Shocks

Challenge: Manufacturers often lack the level of visibility required to navigate market uncertainties. This is key to monitor news and react to changes such as tariffs, exchange rates, labor costs, or raw material constraints. Decisions are often reactive and lack structured evaluation.

Solution: Scenario simulation tools allow manufacturers to run "what-if" analyses and evaluate multiple response strategies in real-time.

Benefit: Informed, confident decisions that factor in trade-offs and outcomes.

3. Boost Production Efficiency

Challenge: Disconnected production, procurement, and logistics functions lead to inefficiencies. Manual processes slow down response time and lead to mismatches in material availability.

Solution: End-to-end planning tools help synchronize supply chain functions and workflows that help teams automate planning tasks while enabling exception handling.

Benefit: Streamlined operations, lower waste, and faster time-to-market.

4. Strengthen Cash Flow Through Smarter Inventory Management

Challenge: The traditional approach of maintaining high inventory "just in case" to avoid stockouts ties up cash and increases storage costs.

Solution: Multi-echelon inventory optimization dynamically adjusts inventory levels (for each product, each location, each period needed such as day, week, month, etc.) based on actual and forecasted demand.

Benefit: Better service levels with less working capital.

5. Support New Product and Market Expansion

Challenge: Traditional planning methods rely on limited historical data or intuition when launching new products or entering new markets. This created challenges with uncertainty in sales projections and inventory needs. Businesses need robust forecasting to efficiently manage inventories and capacity.

Solution: AI-powered forecasting using both internal sales history and external market data.

Benefit: Smarter resource allocation when scaling product lines or entering new geographies.

Overcoming Barriers to Adoption

One of the common concerns in markets like Malaysia is financial prudence, especially under uncertain conditions. But the beauty of supply chain planning solutions is that they typically require modest upfront investment, with clear and rapid ROI when effectively implemented.

Workforce upskilling is another essential component. Tools are only as effective as the people using them. Investing in training programs and drawing lessons from success stories of similar companies can accelerate adoption and maximize value.

The Way Forward

For supply chain leaders across the globe, the Malaysian furniture industry offers a compelling example. The challenges are real and complex, but not insurmountable. Strategic technology adoption provides a clear path forward.

By leveraging digital planning capabilities to improve supply chain visibility and agility, companies can overcome challenges while positioning themselves for long-term success.

Are you ready to adopt smarter supply chain planning that can grow and scale with your business? Let’s have a chat about how we can help you manage uncertainty, build resilience, and drive profitable growth with AI-driven supply chain planning software.