Imagine your company is a high-performance sports car, but instead of speeding along the highway, it's stuck in neutral due to uncertainty surrounding demand, supply, and financial impacts (in car terms, traffic, fuel level and weather). Today’s increasing levels of unpredictability create challenges for many organizations, leading to working capital tied up in inventory, excess capacity, or unused resources. Ultimately, hindering your ability to respond quickly to changing market conditions. You struggle to get from point A to point B because you fail to see the alternate routes.

Traditional supply chain planning methods often fall short in accounting for today’s dynamic landscape, expecting supply chains to operate in an environment of certainty and accuracy, and focus more on following ‘the plan’ versus adapting to real-world impacts.

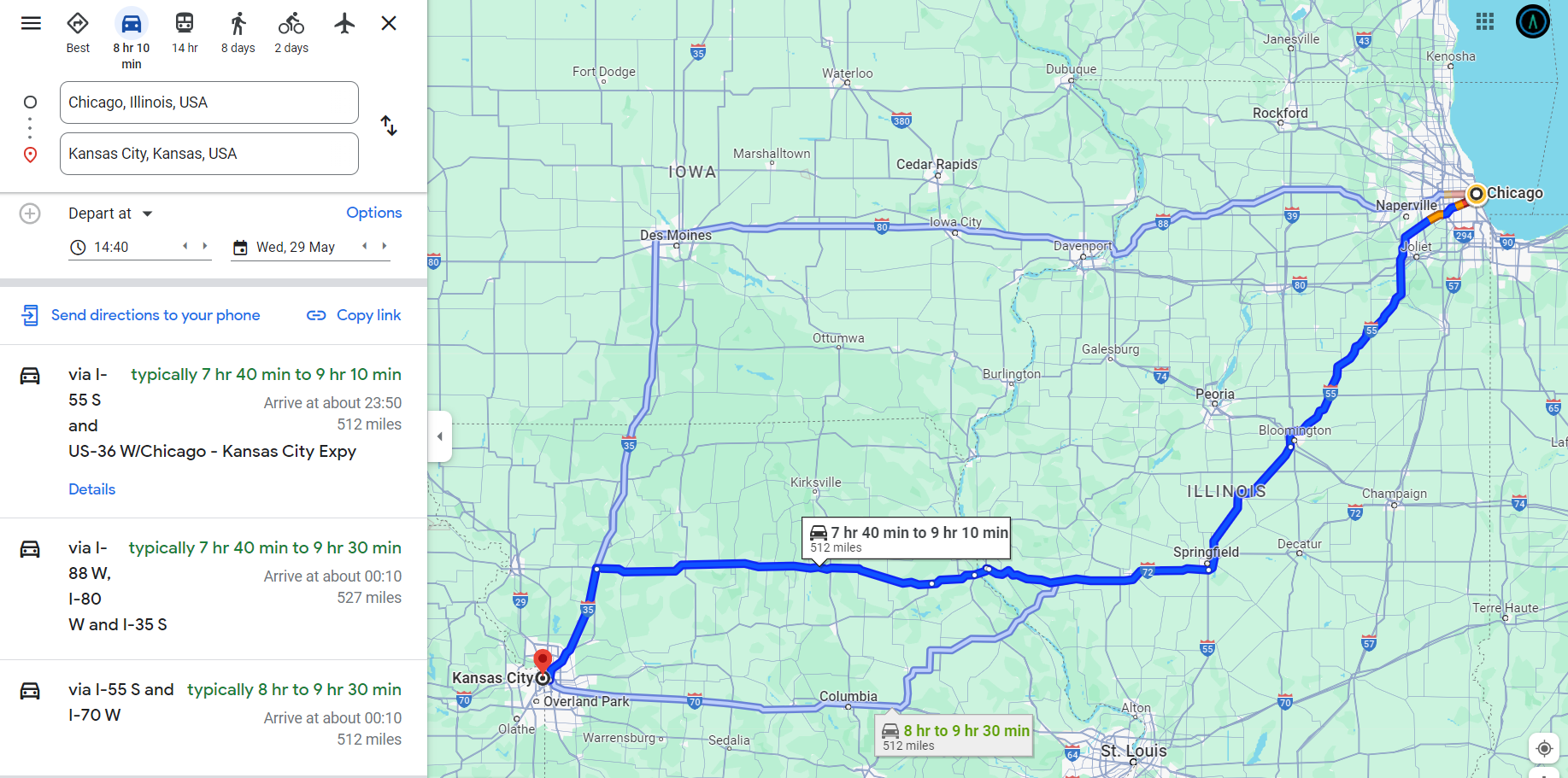

To illustrate the next evolution from certainty and accuracy, let's revisit the car analogy and driving directions. Like supply chain - no two trips will experience the same traffic, weather, etc., but there are ranges of drive times that can be used to inform planning. Thanks to services such as Google Maps, we now see options and the impact of each option. In the example below, traveling from Chicago to Kansas City, we see one route has higher toll costs and takes more fuel but is free of construction that could lead to bottlenecks. We have more data available to make informed decisions, and we get to establish the guiding principles we follow – save money (tolls, gas), save time, reduce turns, avoid highways. Just like supply chains, continuously sensing for accidents and police traps allows drivers to shift routes and speeds based on their tolerance for risk (bottlenecks and speeding tickets).

Changing the game.

To tackle the challenges of variability and unpredictability, we must embrace probabilistic planning, a strategic approach that incorporates probability distributions into decision-making processes.

An end-to-end AI-powered probabilistic planning approach provides a complete model of real-world supply chain probabilities and can model different scenarios, revolutionizing the way companies manage risk and opportunity, and capitalize on uncertainty. This method allows organizations to analyze ranges of possibilities with end-to-end supply chain considerations to create planning policies that account for variability, risk and disruption, with the ability to shift between policies as supply chain needs dictate.

In this article, we’ll explore three use cases that illustrate the power of probabilistic planning and its impact on various aspects of business.

Use Case 1: Uncertainty and Lost Sales

A global leader in plastic compounds and PVCs faced uncertainty due to rapidly changing market demand, supply chain complexity, and decreasing vendor flexibility. This led to missed sales, high inventories, and profit margin compression. They needed an integrated planning system that analyzed trade-offs between customer service, cost structures, cash flow, and resiliency, but quickly realized that a single forecast number lacked the required context to inform strategic planning.

By adopting a probabilistic approach, the company gained deeper insights into their business and the impact of each decision to support its business objectives. Now, they can analyze trade-offs between financial and operational outcomes across organizational levels and functions. The team is now able to assess the full range and impact of disruptions and understand vulnerabilities more accurately. This includes balancing risks and working capital with the flexibility to seize new opportunities to support growth.

The company can now answer key questions such as whether their warehouse and shipping capacity can flex to support varying demand ranges, and the amount of exposure if additional demand doesn't materialize. They can answer how much demand is needed to be profitable with existing capacity as well as the breakpoint between building inventory, adding shifts, and capital investments to expand capacity throughput.

All of these insights allow the company to develop proactive strategies to transform obstacles into opportunities for growth and competitive advantage.

Use Case 2: Supply Disruption

A manufacturer of indoor and outdoor furniture and accessories faced supply chain disruptions due to high seasonality, bulky products, and reliance on third-party suppliers. The launch of a new outdoor product was impacted by a shortage of a critical mechanical part sourced from a supplier who had lost skilled laborers in a competitive market. Despite successfully launching the product, the company recognized the need to rethink their planning processes to enhance supply chain resilience and avoid similar disruptions or unpredictable events impacting their success.

Through experimentation and modeling of multiple scenarios on supply probabilities using the Atlas Planning Platform, several lessons were learned that changed the company's supply chain policies. Internally manufactured parts have higher supply certainty with shorter lead times, leading to a self-inflicted bottleneck. Resiliency could be added through dual sourcing of the externally sourced part, or through incremental safety stock to support differing lead times and supply certainty.

Trade-off analysis revealed that these changes would enhance supply chain resilience at a relatively small cost, improving the ability to cover likely demand levels while minimizing inventory cost exposure – especially when compared to increasing finished goods inventory. The company was able to quantify how single components’ lead time and potential disruption could have a significant impact on the overall supply chain by leveraging supply probability distributions.

This use case also highlights the importance of commercial initiatives and considering financial trade-offs when planning for supply chain resiliency. Such decisions extend beyond moving units across the supply chain. They involve margin and profitability considerations in addition to operational objectives. With a holistic, integrated business planning process that creates policies around probable ranges of supply, this manufacturer was able to transform a challenge into a stronger approach for driving supply chain success.

Use Case 3: Maximizing Profit

A baking company with a mature Integrated Business Planning (IBP) process faced challenges in predicting profitability due to volatility in egg prices and availability, which accounted for up to 20% of raw material costs. To address this, the team incorporated probability ranges of egg costs into their IBP process and defined policies to pivot based on these costs.

By doing so, the organization achieved alignment across sales, marketing, finance, supply chain, and procurement functions. The policies developed thorough trade-off analysis to improve cash flow while managing service level risks:

- In periods of exploding egg prices, the company can switch to using dried eggs in certain products, which involves engaging procurement and adjusting recipes.

- With medium egg price increases, the company will increase finished good prices, while reducing inventory to minimize the impact of higher egg costs. Shortages would be accepted and addressed by allocating products for key customers.

- On the other hand, when egg prices drop, they can secure more eggs, increase production rates, and lower prices and run promotions to capitalize on lower material costs while maximizing their investments in capacity.

The IBP process now enables swift decision-making based on clear thresholds for egg prices, sales volumes, and service level risks. The company has achieved organizational alignment around these decisions, ensuring that all functions work together to maximize profits in response to changes in egg prices.

The Future of Planning is Probabilistic

These use cases showcase the transformative potential of probabilistic planning across different industries. By embracing uncertainty and understanding the probabilities around demand, supply, and financial drivers, companies can gain a competitive edge. End-to-end probabilistic planning empowers companies to turn unpredictability into opportunities for growth, helping them:

- Analyze a Range of Probabilities: Build supply chain strategies that account for the distribution of probabilities and consider most likely ranges.

- Evaluate Likelihood of Disruption: Understand the probability of disruptions and their potential impacts on the supply chain.

- Assess Impact: Consider the frequency and severity of disruptions to make informed decisions that balance risk and opportunity.

- Identify Vulnerabilities: Identify vulnerable areas across the end-to-end supply chain and develop strategies to mitigate risks.

The future of planning lies in moving beyond planning for a single outcome or one-number plans that don’t account for distributions of outcomes or variability. To embrace the unknown, it’s crucial to leverage advanced AI capabilities in supply chain planning to effectively respond to changing conditions. Adopting a probabilistic approach enables companies to navigate uncertainty with an antifragile mindset and increase profitability.

It’s not just about predicting the future; it’s about preparing for it and turning uncertainty into a strategic advantage. Let us show you how.